In the rapidly changing world of electronic gadgets, innovation is necessary to keep ahead of the curve. As the need for smaller and more flexible performance electronic gadgets continues to increase, companies are searching for ways to improve manufacturing processes. Manufacturing using flex circuits is among of the most innovative technologies that has been the subject of a lot of attention.

Flexible printed circuit boards or Flexible Circuits (PCBs), have many advantages over rigid PCBs. They are extremely flexible that can bend, twitch, and conform in various shapes. This makes them suitable for applications which require intricate designs or are restricted by space and enhanced durability.

Flex circuits allow manufacturers to challenge design limits with a flexible base that can adjust to the shape and the size of the device. This flexibility lets designers create more innovative and smaller designs, eventually creating lighter and smaller devices. Imagine a smartphone that seamlessly is curved around the wrist. Wearable health monitor that fits discreetly around the wrist. It’s even a smart gadget that has a seamless and ergonomic design. Engineers and designers can translate their ideas into reality by using Flex Circuits. They allow the creation of a wealth of possibilities in product design.

The endurance of flexible circuits is what differentiates them from their rigid counterparts. Traditional PCBs may be damaged by shocks, vibrations and repeated bends. Flexible circuits are built with specially designed materials that are able to withstand these problems. They are thus extremely resilient even in the most demanding environments. This kind of durability is essential for industries like aerospace, automotive and medical, in which electronic components have to endure harsh environments without compromising their performance.

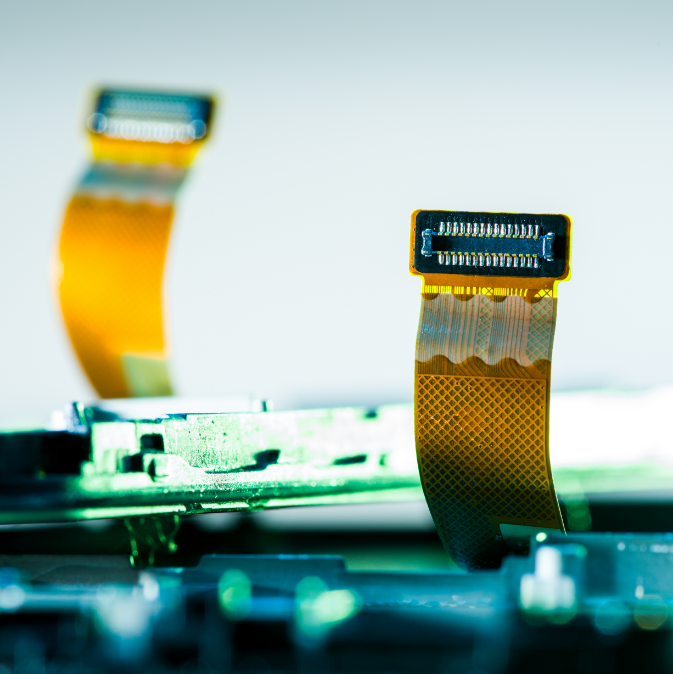

The capabilities of flex circuits are greatly enhanced by the methods of manufacturing that are employed. As opposed to rigid PCBs which are made of multiple layers of fiberglass and copper Flex circuits are created using a thin, flexible substrate material such as polyimide or polyester. The substrate serves as the basis for the circuit that allows it to bend and turn while still ensuring electrical connectivity. Utilizing advanced manufacturing techniques such as flex circuit manufacturing, manufacturers can precisely etch circuit traces connect complex interconnects and integrate components directly onto the flexible substrate.

Surface mount technology, also known as SMT, enables the integration of components onto flex circuits. This allows for greater flexibility and functionalities of these circuits. With SMT manufacturers are able to mount electronic components directly on the surface of the circuit, removing the requirement for bulky connectors and reducing the overall size of the device. This method of operation doesn’t just decrease the dimensions of the device but also improves signal quality, reduces weight, and improves thermal management.

Additionally the manufacturing methods of flex circuits permit efficient prototyping as well as the ability to scale production. Flexibility of circuit design allows rapid iterations when prototyping, speeding the process of developing products. In addition, because they can be made in large quantities with automated manufacturing processes, they are low-cost solutions for production in large quantities. This makes flex circuits a good choice for businesses that want to get their innovative ideas on the market swiftly. For more information, click flex circuit manufacturer

Since the need for flexible electronics continues to increase the need for trustworthy flex circuit makers becomes vital. It is crucial to collaborate with reliable, experienced manufacturers in order to guarantee the quality and consistency of production of flex-circuits. These companies have the knowledge to assist clients throughout the design and manufacturing process, offer valuable insights into the selection of materials, and guarantee the compliance of industry standards.

In the end, flex circuits are invaluable components for achieving the most complex level in contemporary electronic assemblies. They are at the core of various complex systems, ranging from displays in consumer products to military applications. Flexible substrates permit engineers to create designs with a lot of features yet fit within tight dimensions for assembly footprints. Flexible assemblies are more efficient than other circuit routing methods in terms of accommodating size restrictions. Flexible circuits are the most suitable option for projects requiring complex interconnections that combine multiple technology into a well-designed packaging.